مسكن

>

crushed ore jaw crusher

مسكن

>

crushed ore jaw crusher

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

crushed ore jaw crusher

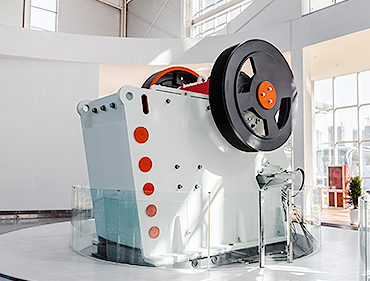

Crushed Ore Jaw Crusher

Crushed Ore Jaw Crusher. Jan 23 2017 The crusher has two vertical jaws a fixed jaw and a swing jaw The rocks to be crushed are filled into the crushing chamber the gap between the two jaws and then a weighted flywheel is used to create an eccentric motion in the swing jaw to provide the required inertia to crush .

Laboratory Crushers 911Metallurgist

Let us make recommendations for type and size crusher for your batch laboratory or continuous or pilot test plant. Laboratory Forced Feed Jaw Crusher The (Type I) Laboratory Forced Feed Jaw Crusher is furnished in two sizes. The 5″x 6″ size is excellent for crushing in ore .

ZGPE(X)jaw crusher Yantai Jinpeng Mining equipment, ore ...

Jaw crusher works though the periodic movement of moving jaw by broken material usually used in coarse crushing stage has feature blew: High production capacity, Great breaking ratio, broken high is a high technological enterprise that integrated research, manufacture, sales and service . The company has multiple subsidiaries such as Mineral Processing Research Institute...

Mine Crusher

Dec 13, 2011· To the jaw crusher, we adopt heavy movable jaw and optimized connect methods, in this way, the hard mining ores can be crushed easily. Obviously, jaw crushers are just primary crushers, they can crush big lumps to small lumps, but the .

Jaw Crusher VS Cone Crusher | Which Is The Better Crusher ...

When wet and viscous ore is crushed, or medium, small concentrators, jaw crushers are suitable. The weight of cone crusher with the same output is about twice that of jaw crusher, so the cost of civil engineering and later maintenance is higher, but the cone crusher has deep crushing cavity, large capacity and low energy consumption.

Jaw crusher,Jaw crushers,Jaw crusher supplier,stone jaw ...

Jaw Crusher [ Capacity ]: 1700 t/h [ Applicable Material ]: Jaw crusher is a kind of stone crushing machine which is widely used as primary or secondary crusher. Baichy manufactures coarse jaw crusher and fine jaw crusher in stationary type or mobile type.

Jaw Crusher Working Principle

A sectional view of the singletoggle type of jaw crusher is shown below. In one respect, the working principle and application of this machine is similar to the Dodge crushers; the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge motion is, however, a more complex one than the Dodge motion, being the resultant of the ...

Small Jaw Crusher 911Metallurgist

The 911MPEJAC34 or 3″ x 4″ (75 x 100 mm) is our biggest Small Jaw Crusher. Handcrafted in Canada, is designed crush rocks/ore of any type (gold, silver, copper, granite, cement, bricks, etc.) 3" (75mm) in size down to 50% passing its CSS closed side setting of 1/8″.

Crusher Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

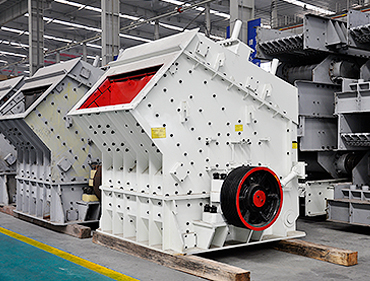

CZS Highefficient Cone Crusher, ore cone crusher, CZS ...

CZS Highefficient cone crusher is a highperformance type optimized and improved on the basis of PY series spring cone crusher. It is widely used in fields of mining, building material, metallurgy, etc. It is suitable for medium crushing and fine crushing on basalt, river stone, granite, quartz, metal ore, etc with high hardness materials.

Jaw Crusher VS Cone Crusher | Advantages and Disadvantages

Jaw crusher breaks the rock to 10 ~ 30 cm size. Cone crushing machine further broke the stone to below 10 cm. Large cone crushers (gyratory crushers) also can as head crushers. Fine jaw crusher also can as a twostage crusher, crushing stone to cm grade particle size range. There are five differences from jaw crusher vs cone crusher. Crushing ...

Jaw Crushers Variable Sized Material Reduction Equipment ...

They take large pieces of rock, ore, concrete, or other materials, and crush them down to smaller sizes, for further processing in a ball or hammer mill, or for use in ballast or fill applications. Standard features include: Complete and ready to run including jaw crusher, belts, motor, fullenclosure guards, all integrated on a steel skid

Crushing in Mineral Processing

In mineral processing or metallurgy, the first stage of comminution is crushing.. Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks. In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface.

Jaw Crushers 911Metallurgist

This crusher is the finest of our lines of jaw crushers which we offer. Others include: Superior, Type "B" Blake, FineReduction and Dodge — sizes, 4 by 6 to 84 by 66 inches. A reciprocating machine, the crushes material in a straight line between jaws — without grinding or rubbing surfaces. LOWER JAW CRUSHING COSTS As you compare this jaw crusher feature for feature with other makes ...

: TECHTONGDA Jaw Crusher Rock Crush Machine ...

This jaw crusher is made of manganese steel which is much harder than carbon steel. This machine is applicable to medium and fine crushed materials for the purposes of laboratory and production and primarily provided as environmental protection equipment.

Metal ore broken,Iron Ore Crushing,Copper Ore Crushing ...

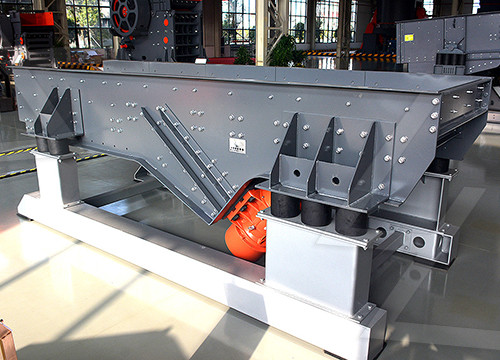

The technological process for the metal ore designed by Zhongxin Heavy Industry, satisfies the client''s requirement greatly for the various metal ores crushing. The metal ore will be evenly conveyed by vibrating feeder to jaw crusher for primary crushing, the crushed material will be conveyed by belt conveyor to cone crusher for further ...

Gold ore concentration plant, gold crusher, gold crushing ...

Gold ore concentration equipment. In gold concentration, high technology gold mining equipment, such as gold detectors, elegant modern dredges, and lightweight sluices will be needed. Gold crusher is also used as the primary crusher in gold ore crushing industry. Jaw crusher is the most used gold mining machine for crushing ore.

: 100X60 Mini Jaw Crusher for Rock Ore Slag ...

Buy 100X60 Mini Jaw Crusher for Rock Ore Slag Steel Slag Coal Stone Crushing 220V#: Juicer Parts Accessories FREE DELIVERY possible on eligible purchases

PE Jaw Crusher Rock Crusher Manufacturer, Types of Ore ...

The PE series jaw crusher is usually used in the production lines of various hardest stones, ore crushing and recycle materials as primary and secondary stage crusher. jaw crusher is designed for materials whose compression strength is no more than 320Mpa.

New Used Rock Crushers for Sale | Iron Ore Crushing ...

Rock Crushing Equipment and Iron Ore Crushing Machines for Sale Savona Equipment is a hard rock crushing equipment supplier worldwide. Mining operations use crushers of all types for various applications, with primary and secondary crushers handling coarse materials, and tertiary and quaternary crushers reducing ore particles to finer gradations.

What is a Jaw Crusher and How Does it Work? OreFlow

Mar 28, 2019· A jaw crusher is a large piece of equipment that''s used in mine and ore processing plants to crush rocks. The equipment was first introduced back in 1858 by inventor Eli Whitey Black who primarily developed machinery used for crushing stone.

(PDF) SIZE REDUCTION BY CRUSHING METHODS

Crushing of ore and minerals. There are three stages in crushing as stage 1, 2 and 3. ... A jaw crusher is generally used as a prim ary crusher in a crushing circuit.

Jaw Crusher | Jaw Stone Crusher | Crushing Equipment ...

According to the stage of the crushing process, the machine can be classified into primary jaw crusher and secondary jaw crusher, though it is mostly used as the first stage of stone crushing. Depending on your application requirements, the crusher can be configured in stationary or wheeled mobile design. Benefits of Using Jaw Crusher

: Patented Hand Operated Jaw Type Ore Crusher ...

Buy Patented Hand Operated Jaw Type Ore Crusher Grinder: Arts, Crafts Sewing ... The CrazyCrusher manually operated rock crusher is designed to crush and grind ores in the field or at home to test and sample for valuable deposits. This is NOT for production purposes, but for assay work in the field or at home to crush samples to determine ...