مسكن

>

recycling of metal slag

مسكن

>

recycling of metal slag

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

recycling of metal slag

Nonferrous metal recycling: Recovery of nonferrous ...

The product (ZORBA) of the nonFe separator is a valuable input for all manner of nonFe metal recovery plant as a means of separating and recycling the nonFe metals contained. Customers for nonFe products include dry mechanical process operators, manual sorting plant, wet mechanical systems and secondary smelting operators.

Recycling SAW Slag Proves Reliable Repeatable Harbert ...

Jul 11, 2018· The objective of this testing was to classify the recycled slag as an F7 A2EM12 K, which means the testing of the coupon welded with the recycled slag will produce weld metal with an aswelded tensile strength no lower than 70,000 psi (480 MPa) and Charpy Vnotch impact strength of at least 20 ftlb (27 J) at 20°F (29°( ) when produced with an EMl 2K electrode under the conditions ...

Table of Contents US EPA

metal generators, scrap metal recyclers, and EAF operators for managing lead in scrap. These include visual inspection of scrap loads and magnetic or other types of physical separation.

Rotary Dross / Slag Metal Reclaimers

DIDION Rotary Dross / Slag Metal Reclaimers liberate and reclaim valuable metallics from large slag dross chunks using a patented design. The machine features a Dynamically Isolated Articulated Concentric Crusher with serrated teeth that provides a positive action for reducing large chunks.

Disposal and Reuse Options for Used Sandblasting Grit ...

Disposal and Reuse Options for Used Sandblasting Grit . ... Alternatives to sand abrasives include other mineral sands with no free silica, metal slag, and coal slag. Coal slag has been used frequently as a blasting material. ... Rock Garnet Trading is a distributor of various sand blasting abrasives and blasting equipment.

Steel Slag Material Description User Guidelines for ...

Steel slag, a byproduct of steel making, is produced during the separation of the molten steel from impurities in steelmaking furnaces. The slag occurs as a molten liquid melt and is a complex solution of silicates and oxides that solidifies upon cooling.

Metal Recycling | Metal Casting Resources

Scrap pieces with similar properties are loaded into a large furnace and heated to the appropriate melting temperature for the metal. In the refinement process, slag forms and floats to the top of the molten metal. Slag is the stony waste matter separated from metals during refining.

Slag Wikipedia

Slag is the glasslike byproduct left over after a desired metal has been separated (, smelted) from its raw ore. Slag is usually a mixture of metal oxides and silicon dioxide. However, slags can contain metal sulfides and elemental metals.

Characteristics and utilisation of copper slag—a review ...

Utilisation and recovery of metal depend on the type of slag. Current options of management of this slag are recycling, recovering of metal, production of value added products and disposal in slag .

Nonferrous recycling | Recco

Recco. As a specialist in the recovery of nonferrous metals from slags, or bottom ash (IBA), Recco facilitates a stateoftheart system that separates the aluminium and heavy metals in 3 grading sizes from residue aggregates. The yield of aluminium and heavy metals we generate with our onsite bottom ash processing installations is, on average, 1,5 % higher than conventional recovery systems ...

Advances in slag recycling and reuse UK Essays

INTRODUCTION: Slag is the unavoidable by product that comes with the production on any metal that is being produced today. This by product that is produced or added as a synthetic slag in the steelmaking process is used to remove undesirable impurities and nonmetallic inclusions by bonding or .

Metal slag processing // REMONDIS´ Lippe Plant

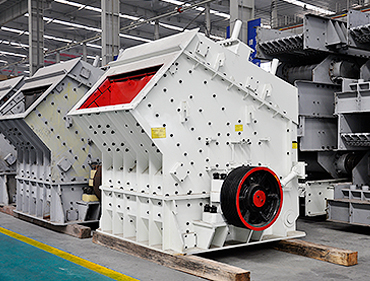

The special feature of LEGRAN''s metal slag processing system at the Lippe Plant is the way the material is treated. The slag and spent refractories need to be pulverised before they can be processed and this job is carried out by a rod and ball mill which dates back .

Slag: From Metals Byproduct to Valuable Construction Material

Slag is a byproduct of the metallurgical smelting process. Slag has a double role: it permits removal of impurities, known as gangue, from the melt by forming oxides. It also allows exchange reactions with the liquid metal, permitting control of the process in order for the desirable elements to ...

Rare Minor Metals Recycling | Vital Materials

Recycling of rare metals and precious metal wastes can make a huge contribution to the cause of environmental protection. Raw materials are never inexhaustible resources, and recycling provides for sustainable development. Vital Materials can provide recycling services for the following materials:

Recycling Gold from Scrap Metal: Process and Equipment

The flowsheet presented was developed for recovery of uranium metal from magnesium metal and a magnesium fluoride slag. By this process it was possible to release appreciable valuable metal which was tied up in the slag and not recoverable in the initial production process.

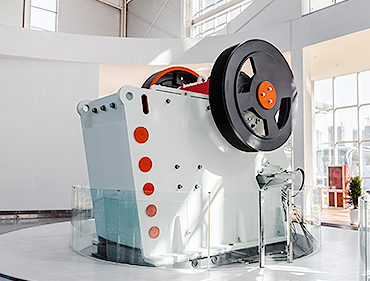

Metal Slag Recycling Plant Slag Processing Plant ...

Manufacturer of Metal Slag Recycling Plant Slag Processing Plant offered by Laxmi Enfab Private Limited, medabad, Gujarat.

Slag Pots | Scrap Metals Engineered Products | Metal ...

slag pots Get the engineered products you need for your industrial company by turning to RAMM Metals, Inc. We are a fullservice importexport marketing and distribution company that caters to the steel, iron ore and mining industries.

Treatments and Recycling of Metallurgical Slags | IntechOpen

In this chapter, techniques for the treatment and recycling of metallurgical slags are described. Metallurgical slags are considered secondary raw materials and are used or added during the process to improve steelmaking practice. Steelmaking slag added into ladle slags makes it possible to minimize slag .

Steel slag in China: Treatment, recycling, and management ...

Steel slag recycling is a serious problem in China. The volume of steel slag is growing rapidly because the output of steel is steadily increasing; however, slag''s utilization remains relatively low. The utilization rate in China is only %, whereas the utilization rate of steel slag in industrial countries is .

Aluminium Recycling Plant,Metal Slag Recycling Plant,Non ...

Aluminium Recycling Plant,Metal Slag Recycling Plant,Non Ferrous Recycling Plant offered by DHANVANTI ENGINEERING, us for various Recycling Plant.

Solutions for metal recycling to recover valuable residues ...

Both raw materials and valuable residues that are used in product design are growing increasingly complex. Today, therefore, flexible and forwardlooking technologies are required in the materials processing industry. And we have them: innovative, sensorbased solutions for high sorting depths, resulting in effective metal recycling.

What is the importance of slag composition in recycling of ...

Regenerator slag that is recycled to the DeP furnace, on the mass of slag generated in each unit process; the phosphorous distribution between metal and slag; process heat requirements and the ...

Recycling Ash / Slag Goudsmit Magnets

The resulting product is a slag mass, called IBA (incinerator bottom ashes). This consists mainly of two main parts: metal and mineral fractions. Incinerator slags are usually first buffered (aging) and then upgraded in what is called an SCF (slag cleaning furnace). The metal fraction consists of both ferrous and nonferrous metals.

3 Iron Unit Recycling Department of Energy

3 Iron Unit Recycling On a weight basis, steel is the most recycled material in use today (Figure 31). The 70 million net tons of steel recycled in 2000 were used to produce about 112 million net tons of new steel in the United States.